2024/8/2 14:25:47

Resources

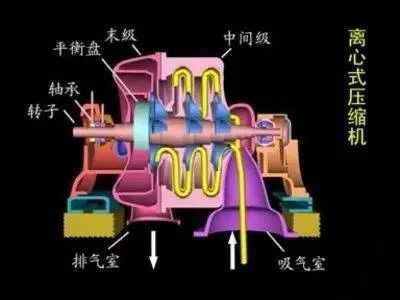

Introduction and Performance of Centrifugal Compressor

Centrifugal compressor is a vane rotary compressor (i.e. turbine compressor). In centrifugal compressors, the centrifugal force of the gas given by the high-speed rotating impeller, and the diffuser effect of the gas given in the diffuser channel, so that the gas pressure is increased. Early, because this compressor is only suitable for low, medium pressure, large flow occasions, but not for people's attention. Due to the development of the chemical industry, the establishment of various large-scale chemical plants and refineries, centrifugal compressors have become the key machines for compressing and transporting various gases in chemical production, and occupy an extremely important position. With the achievements of gas dynamics research, the efficiency of centrifugal compressors has been continuously improved, and due to the successful development of key technologies such as high pressure seal, processing of narrow impeller with small flow, and multi-oil wedge bearing, a series of problems have been solved in the development of centrifugal compressors to high pressure and wide flow range, so that the application range of centrifugal compressors has been greatly expanded, so that it can replace reciprocating compressors in many occasions. And greatly expand the scope of application.

It's advantage. Centrifugal compressors can obtain such a wide range of applications, mainly compared to piston compressors have the following advantages. Firstly, Centrifugal compressor has large gas capacity, simple and compact structure, light weight, small unit size and small footprint. Secondly, it runs balanced, reliable operation, high operating rate, less friction parts, so spare parts need less, less maintenance costs and personnel. Thirdly, in the chemical process, the centrifugal compressor can achieve an absolutely oil-free compression process for the chemical medium. Finally, centrifugal compressor is a rotary movement of the machine, it is suitable for industrial steam turbine or gas turbine direct drive. In general large-scale chemical plants, by-product steam is often used to drive industrial steam turbines, which provides the possibility for comprehensive utilization of heat energy. However, centrifugal compressors also have some shortcomings.

It's disadvantage. Firstly, centrifugal compressor is not suitable for too small volume and pressure ratio is too high occasions. Secondly, the stable working zone of the centrifugal compressor is narrow, and the gas volume adjustment is more convenient, but the economy is poor. Thirdly, the efficiency of centrifugal compressor is generally lower than that of piston

compressor.