Products

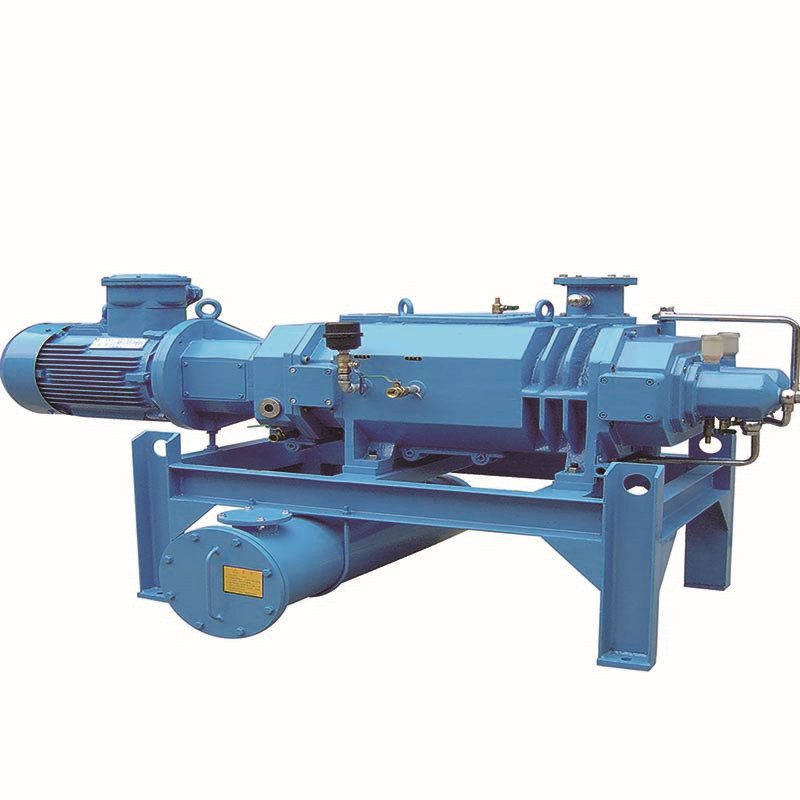

Screw Vacumm Pump

Model ALP Series

• The screw vacuum pump uses the suction and exhaust action generated by

synchronous high-speed reverse rotation of the screw in the pump

housing to achieve the role of pumping. It is the replacement of

oil-sealed vacuum pump, which can remove a lot of water vapor and dust

gas occasions. It is widely used in pharmaceutical, chemical,

semiconductor and other enterprises with high requirements for clean

vacuum.

• ALP series screw vacuum pump unique design of air inlet channel, directly from the outside suction, reduce the number of fan opening, reduce the fan energy consumption.

• The motor cooling channel ensures that the heat is directly discharged from the outside of the chassis and not trapped inside the chassis, so as to achieve a lower suction temperature and reduce the increase in energy consumption caused by compression of high temperature air.

• The air inlet channel and the motor cooling channel can act as a sound insulation cover to reduce noise.

• Built in the most advanced monitoring system specially designed for vacuum pumps, easy to operate and powerful. Monitor the operating status of the vacuum pump in real time, record the running time, programmable timer, temperature/pressure values, set point control, etc.

• ALP series screw vacuum pump unique design of air inlet channel, directly from the outside suction, reduce the number of fan opening, reduce the fan energy consumption.

• The motor cooling channel ensures that the heat is directly discharged from the outside of the chassis and not trapped inside the chassis, so as to achieve a lower suction temperature and reduce the increase in energy consumption caused by compression of high temperature air.

• The air inlet channel and the motor cooling channel can act as a sound insulation cover to reduce noise.

• Built in the most advanced monitoring system specially designed for vacuum pumps, easy to operate and powerful. Monitor the operating status of the vacuum pump in real time, record the running time, programmable timer, temperature/pressure values, set point control, etc.