2024/8/19 17:40:08

Resources

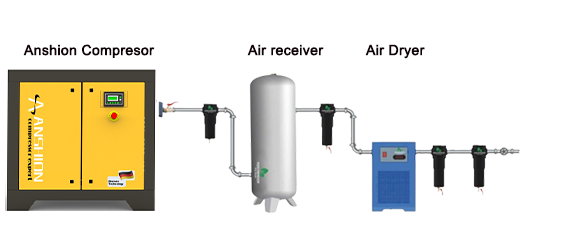

Why do air compressors need to be equipped with air receivers?

There are several reasons why air

compressors need to be equipped with air receivers, which together ensure the

stable operation, efficiency improvement, and equipment protection of the air

compressor system. This article will provide a detailed explanation of this

issue.

First, Balancing and stabilizing air

pressure

During operation, air compressors produce

compressed air, but gas consumption is not continuous and has certain

fluctuations. If the air compressor is directly responsible for responding to

this fluctuation, it will cause instability in its operation, and even damage

the equipment. The air receiver acts as a buffer device, effectively balancing

the gas fluctuation and maintaining the stable air pressure in the system. When

the air compressor produces more gas than the system consumes, the excess gas

is stored in the air receiver; when the system needs more gas, the air receiver

releases the stored gas to meet the system's needs. This balancing action

ensures stable operation of the air system and avoids equipment damage or

unstable operation caused by pressure fluctuations.

Second, Reducing energy consumption and

extending the life of air compressors

Air compressors consume a lot of energy

during startup and shutdown, especially the current during motor startup is

much greater than the normal operating current. By storing the compressed air

in the air receiver, the air compressor can operate at a constant pressure,

which reduces the energy consumption during startup and shutdown. Additionally,

the air receiver can also act as a buffer for the air pressure, reducing the

pressure fluctuations and extending the life of the air compressor. Frequent

starting and stopping not only increases energy consumption, but also

accelerates the wear and tear of the air compressor, shortening its service

life. The presence of an air receiver can significantly reduce the number of

start-ups and shutdowns of the air compressor. When the system's demand for gas

fluctuates within a certain range, the air receiver can release or store gas,

thus avoiding the frequent starting of the air compressor. This not only

reduces energy consumption, but also reduces the wear and tear of the air

compressor, extending its service life.

Third, Improving the stability of the air

system

The air receiver not only balances the

pressure, but also acts as a buffer to reduce the impact of airflow on the

system. Installing an air receiver between the air compressor and the air-using

equipment can make the flow of gas more stable and avoid equipment damage or

instability caused by airflow impact. In addition, the air receiver can also

improve air quality. After leaving the air compressor, compressed air will stay

in the air receiver for a period of time. During this period, impurities,

moisture, and other foreign substances in the air will settle down, and the

temperature of the air will decrease, thereby improving the quality of the air

delivered.

Fourth, Ensuring the automatic shutdown of

the air compressor

After the air volume in the air receiver

reaches a certain level, the unit will automatically shut down, thereby

reducing the unit's energy consumption. This function is of great significance

for energy saving and cost reduction. Meanwhile, it also avoids the unnecessary

running of the air compressor in the idle state, further improving the system's

efficiency.

Fifth, responding to sudden demand

In some cases, the gas consumption of the

air-using equipment may suddenly increase. If there is no air receiver as a

buffer at this time, the air compressor may not be able to meet this sudden

demand in time, leading to production interruption or equipment failure. The

existence of an air receiver can ensure that there is enough compressed air

available for use during sudden demand, thus ensuring the continuity and

stability of production.

Sixth, safety considerations

The air receiver, as a pressure vessel, is

designed and manufactured in accordance with strict safety standards. It can

withstand to some extent the changes in internal pressure and external impacts,

ensuring the safe operation of the system. At the same time, the air receiver

is equipped with various safety accessories, such as pressure gauges and safety

valves, for monitoring and controlling the pressure state of the system and

preventing dangerous situations such as overpressure from occurring.

In summary, the reasons for equipping an

air compressor with an air receiver include balancing and stabilizing pressure,

reducing energy consumption and extending the life of the air compressor,

improving the stability of the air system, ensuring the automatic shutdown of

the air compressor, responding to sudden demand, and safety considerations.

These reasons work together to ensure the stable operation and efficient

operation of the air compressor system. In practical applications, users should

select the appropriate type and specifications of air receiver based on their

own needs and conditions to ensure that the system achieves the best operating

effect.