2024/8/23 10:52:47

Resources

What are the advantages of combining air compressor and inverter

The operation mode of many air compressors is loading and unloading pressure, and the most common energy regulation mode is intermittent control operation, that is, when the ambient temperature is higher than the set value, the time and space press starts, and the time and space press stops below the set value. There are often frequent temperature changes in production activities, and repeated starting and stopping of air compressors consumes a lot of energy, increasing the loss between machine parts.

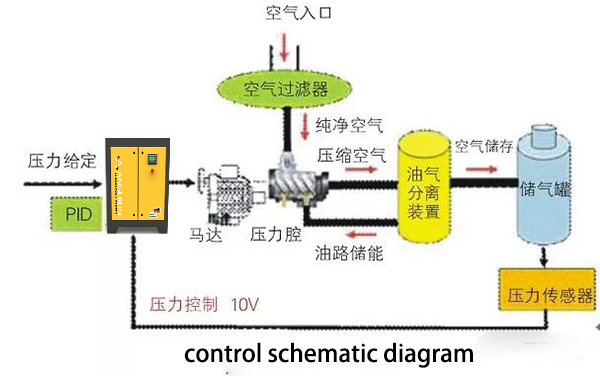

The control principle of frequency conversion control is that the cooling capacity of the air compressor is proportional to the mass flow rate through the pressure transmission, and then the pressure changes until the pipe network pressure is the same as the constant pressure value.

In recent years, China's voice for energy conservation and emission reduction is getting higher and higher, and the demand for energy saving equipment is also increasing. Increasing energy conservation has also become a realistic task facing the air compressor industry. Variable frequency air compressor is an energy saving air compressor, its advantages are as follows:

Advantage 1: Improve the accuracy of pressure control

The addition of the inverter can effectively improve the more accurate pressure control ability, and can effectively adjust the output gas of the compressor, so as to change at any time with the speed of the motor. The frequency conversion control speed has higher accuracy, and the system pressure change can be controlled within the range of 0.2bar, so as to improve the quality of the compressor working condition.

Advantage 2: Reduce operating costs

Traditional compressors always produce idling losses at rated speed during operation, and energy costs can be greatly reduced after conversion transformation. In addition, the loss impact on the equipment is reduced after the frequency conversion start-up, and the future maintenance costs will also be reduced, helping to reduce the operating costs of the enterprise in the long run.

Advantage three: Saving energy

In the normal operation of the air compressor, most of the time is carried out under the condition of non-full load, which will inevitably cause energy waste for a long time. After the air compressor is added to the speed control controller, the motor is controlled by the speed control controller, which can have higher efficiency and save energy.

Advantage four: Extend the service life of the compressor

The frequency conversion speed regulation system takes the output pressure as the control object, and the current is small when starting, and there is no impact on the power grid, so that the motor can achieve soft stop to avoid the damage caused by the current, which is conducive to extending the service life of the equipment.

Advantage five: Reduce noise

The addition of the inverter reduces the rotation frequency of the motor and reduces the noise during rotation. Field measurement shows that the noise can be reduced by 3-7 dB compared with the original system. In addition, the action of the traditional compressor repeatedly loading and unloading pressure is eliminated, and the noise in this action will no longer exist.

In summary, The air compressor is coupled with a frequency converter, and the frequency converter is used to effectively adjust the frequency of the air compressor, saving a small amount of power costs. It not only saves resources to a certain extent, but also improves the work efficiency of the air compressor system, which can bring more benefits to enterprises.