2024/9/5 11:20:25

Resources

Air compressor noise pollution and prevention measures

As a key equipment for continuous operation in industrial production, air compressor is a kind of forte equipment. Air compressor noise level is high, low frequency is prominent, the transmission distance is far, the pollution range is large, causing dizziness, nausea, tachycardia, hypertension and other symptoms. The strong noise generated at work worsens the working conditions and living environment, and not only leads to the decline of people's work and quality of life, so we need to take certain measures to prevent noise. This article will provide you with professional noise control solutions to solve your problems.

First, understand the noise pollution of air compressor

The noise pollution generated by the operation of the hollow press mainly comes from the operation of the motor, the flow of gas and the impact between the machinery and other factors. Their transmission routes are also different:

Motor noise: The motor of the air compressor will produce electromagnetic noise during operation, mainly through air transmission.

Mechanical noise: The piston and other mechanical parts inside the air compressor are mechanical noise generated by friction, wear and uneven transfer of interinstitutional force during high-speed operation. Many parts of the air compressor are in high-speed operation and reciprocating motion process, resulting in tube wall friction, impact and vibration. It's mainly airborne.

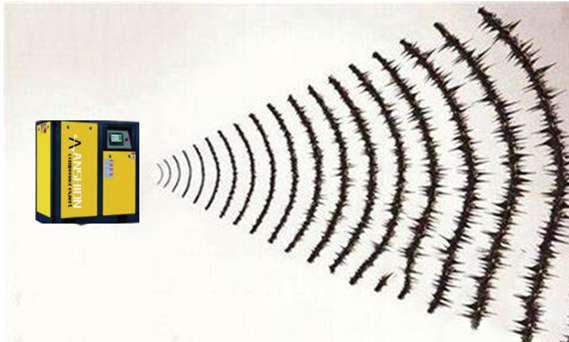

Air flow noise: When compressed air, the air flow speed becomes faster and produces air flow noise (mainly through the inlet and exhaust port radiation), and the gas in the air compressor housing constantly completes the periodic inhalation, compression and exhaust activities. A pressure fluctuation is generated near the intake, which radiates out of the intake in the form of sound waves, resulting in intake noise. Intake noise is about 95dB(A), the air intake noise is 7 to 10 dB(A) higher than the noise of other components, and is the main noise source of air compressors.

Second, there are the following ways of transmission:

Airborne: Noise is transmitted through the air and affects the surrounding environment. The further the distance of this transmission mode, the more obvious the noise attenuation.

Solid propagation: Noise is transmitted through solids, such as pipes, walls, etc., this mode of propagation is closer and the noise attenuation is smaller.

Structural propagation: Noise is transmitted through the structure of the air compressor itself, such as the fuselage, base, etc., and this mode of propagation will also have a certain impact on the surrounding environment.

Third, the impact of air compressor noise on the human body and the environment

The impact of air compressor noise on the human body is mainly manifested in the following aspects:

Hearing damage: Long-term exposure to a high noise environment will cause damage to people's hearing, leading to hearing loss and even deafness.

Psychological stress: being in a high noise environment for a long time will make people feel irritable, affecting work efficiency and quality of life.

Physiological reaction: The high noise environment will also cause physiological reactions, such as rapid heartbeat, elevated blood pressure, etc., which will have adverse effects on human health.

Fourth, air compressor noise protection measures

1. Choose the right air compressor model number: When selecting air compressor, it is necessary to consider its noise reduction performance. Some air compressors have noise reduction design, using sound insulation materials, noise reduction devices, vibration reduction devices, etc., can effectively reduce noise.

2. Install appropriate noise reduction measures: In addition to selecting air compressor models with good noise reduction performance, other noise reduction measures can also be taken to further reduce noise. First of all, soundproof enclosures or sound insulation walls can be set up around the air compressor to isolate noise transmission. Secondly, a noise suppressor or silencer can be added to reduce the noise of the air compressor exhaust port. In addition, the vibration reduction device can also be used, and the sound insulation pad is used to float the ground on the ground inside the air compressor room, which can improve the sound insulation and shock absorption effect of the ground and weaken the ground transmission rate of the air compressor vibration. Through reasonable noise reduction measures, the noise generated by the air compressor can be significantly reduced and the comfort of the working environment can be improved.

3. Regular maintenance and maintenance: the normal operation of the air compressor is very important to reduce noise. Regular maintenance and maintenance can keep the air compressor in good condition and reduce the possibility of noise generation. First of all, it is necessary to carry out regular maintenance according to the manufacturer's guidance, such as cleaning the filter element, replacing the lubricating oil, etc. Secondly, it is necessary to regularly check and adjust the parameters of the machine to ensure its smooth operation and reduce noise. In addition, timely repair of faults and replacement of worn parts are also important measures to reduce noise. Regular maintenance and maintenance can extend the service life of the air compressor and maintain its noise reduction performance.

To sum up, choosing the right air compressor model number, installing the right noise reduction measures, and regularly maintaining and maintaining the air compressor are important points of attention to reduce the noise of the air compressor. Through these measures, the impact of noise on the working environment and employee health can be reduced, and work efficiency and comfort can be improved.