2024/10/22 11:07:39

Resources

How to save energy and reduce emission of air compressor?

Compressed air, as one of the power sources of

manufacturing enterprises, needs to be continuously operated to ensure the

stability of the supply air pressure, which is the basic conditions for the

production and operation of enterprises, and as the main manufacturing

equipment, the air compressor unit is the core equipment to undertake this

task, and constantly needs continuous and reliable operation to ensure

trouble-free and stable operation. Since it is running equipment, it needs

power supply to run, and large power consumption is the core of cost increase.

Below I will introduce some tips that can make air

compressors energy saving and emission reduction, enterprises can take measures

and improve according to their own situation.

First, replace the energy-saving compressor

In today's industrial field, screw compressors have

become the largest type of compressor due to their rugged, easy to maintain

characteristics, and are very versatile. However, the energy efficiency of

screw compressors still hovers at a low level, and only about 20% of the

electricity input to screw compressors is converted into effective compressed

air power, and the rest is converted into heat. If the efficiency of the screw

compressor itself is improved to achieve energy-saving screw compressors, then

great benefits will be obtained.

Screw compressors or centrifugal compressors of

higher energy efficiency can be selected through selection and calculation, but

the amount of investment in this way is relatively large, unless the user

enterprise has the intention, otherwise it is not recommended.

Second, gas transmission pipeline and end

optimization energy saving

Once the compressed air is produced, it needs to be

transported to the use of the gas storage tank and pipeline, and in the

transmission process, there are often problems in the pipeline, which increase

energy consumption and cause unnecessary waste. The energy saving of compressor

system can be realized greatly through the energy saving method of optimizing

the gas link of the pipeline and the end.

1. Insufficient capacity of gas storage tank

In the application site, the problem often occurs

is that the capacity of the gas storage tank is insufficient, because the

capacity is small, the energy storage effect is poor, and the pressure

fluctuation is large, resulting in repeated loading and unloading of the

compressor, forming a large amount of energy waste. By increasing the gas

storage tank, the single unloading time exceeds a certain time, then the

compressor unloading power consumption will decrease, forming an energy-saving

effect.

2. Right Angle elbow

The right Angle elbow at the connection of the

pipeline has a great damage to the energy efficiency, and the reasons are:

A. The right Angle elbow forms a gas impact, and

the local pressure increases, causing the compressor to continue to operate in

a high pressure state, and it is easy to unload.

b, the right Angle elbow causes the flow resistance

to increase, forming an additional work point.

For the right Angle elbow of the compressor outlet,

the pressure of 0.5bar can be depleted in serious cases. If the 6.5bar pressure

system is used on site, the energy loss of the right Angle elbow accounts for

more than 7%, and the degree of harm can be seen. Rational optimization of

pipeline connection points can significantly reduce the energy loss, and this

part of the loss is almost eliminated.

3. The pipe goes improperly

After the compressed air is sent out from the

unified gas storage tank, it is transported to the gas link through various

pipelines. The efficient transmission forms are single point Daisy chain and

multi-point ring. However, the general user site because of one-time investment

savings and other reasons, the direction of the air pipeline is often

unreasonable, resulting in excessive pressure loss, resulting in a higher gas

pressure must be supplied. For example, the general pneumatic field end

pressure can work stably as long as it is greater than 4.5bar, but due to poor

pipeline direction, the compressor must supply 6.5bar pressure, if the pipeline

direction optimization, only 5.8bar pressure can be supplied, and the energy

saving rate can reach about 10%.

4. Insufficient peripheral energy storage

In a production line, there are different types of

gas links, such as:

A. Continuous use of gas links, such as air motors

(hand-held grinding machines), requires continuous and reliable pressure;

b, small-scale pulse type gas links, such as

pneumatic screwdriver, pneumatic piston, etc., require continuous and reliable

pressure; c, large-scale pulse type gas links, such as gas ash removal,

injection equipment, etc., require large energy storage;

d, open gas links, such as glass cooling, purging

links, etc., require large flow, no clear requirements for pressure.

Since the above various gas links often coexist on

the same section of pipeline, pulse gas equipment needs a large instantaneous

gas supply, they are bound to pull down the pipeline pressure, resulting in

continuous gas links not enough pressure, which requires the gas supply end to

supply greater pressure, resulting in a significant increase in compressor

energy consumption. By detecting air pressure and air flow, gas storage tanks

can be deployed in the exact position to increase local energy storage and improve

local air pressure, so that the overall gas supply pressure can be reduced, and

better energy saving effect can be achieved.

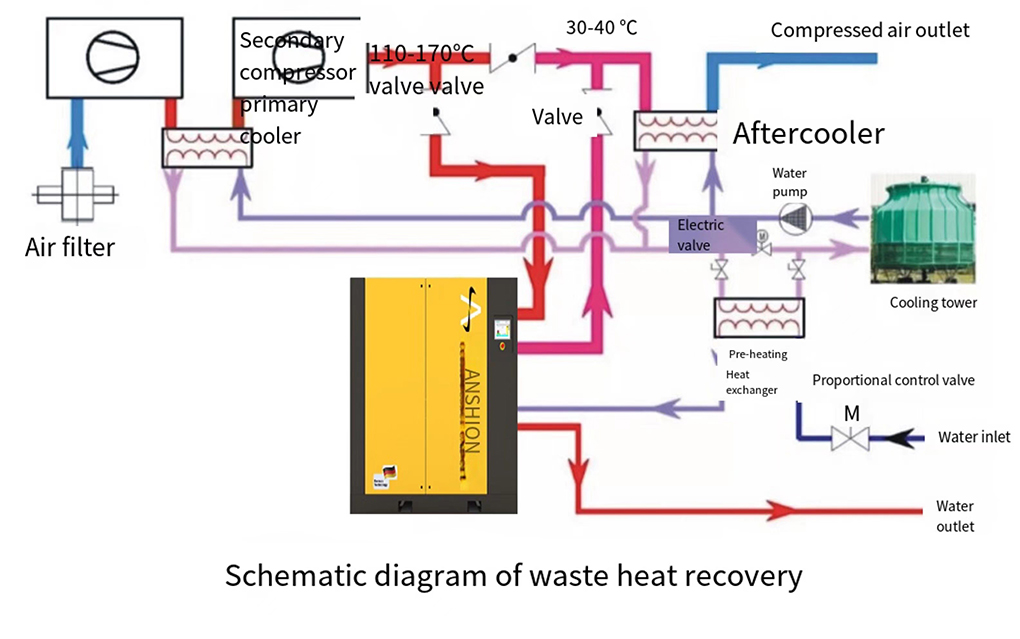

Third, the compressor waste heat utilization energy

saving

The production process of compressed air is more

complex, in the process of gas compression, the degree of heating is high, often

reaching about 100 degrees Celsius, and only about 20% of the energy consumed

by the compressor is converted into compressed air power, and the remaining 80%

is converted into heat. Therefore, the waste heat utilization value of the

compressor is often high.

1. Compressor waste heat to produce hot water

Use the hot oil and hot air during the operation of

the compressor for heat exchange, transfer the heat to the soft water medium,

and then transfer the heat of the soft water medium again to the hot water used

by the user, two-stage heat exchange, to achieve the utilization of waste heat.

This method of waste heat utilization is mainly for occasions with more

compressors and more hot water demand. For example, various enterprises in the

south have compressors running for a long time, and the staff dormitory needs

hot water bath; Coal mine, with a large number of compressors running, and

workers bathing hot water is large.

2. Compressor waste heat cooling

Use the heat energy during the operation of the

compressor to produce high temperature hot water, and then use high temperature

hot water as a heat source to drive the lithium bromide unit refrigeration,

which can produce frozen water to supply the production link. For example,

pharmaceutical companies use the waste heat of centrifugal compressors to

produce hot water to drive the refrigeration of lithium bromide units, make up

for the shortage of frozen water, greatly reduce the utilization rate of refrigeration

compressors, and save energy. Electronics companies use the waste heat of

compressors to produce hot water, drive lithium bromide refrigeration, and

produce chilled water to supply air conditioners and production lines in

production workshops.

In short, the energy-saving measures of screw air

compressors and middle and high pressure air compressors involve many aspects,

which need to be comprehensively considered from the aspects of purchase,

operation parameter adjustment, energy-saving technology application and

maintenance management. Only comprehensive measures can be taken to minimize

energy consumption and improve the operating efficiency of air compressors.