2025/4/8 8:42:16

Resources

Introduction of waste heat recovery technology of air compressor

In modern industrial production, air compressors, as the key equipment to provide compressed air, are widely used in machinery manufacturing, chemical industry, metallurgy, electronics, medicine, food and other industries. However, most of the energy consumption during the operation of the air compressor is wasted in the form of heat energy, which is not only a waste of energy; It will also increase the operating costs of enterprises. With the in-depth promotion of the concept of energy saving and environmental protection, the waste heat recovery technology of air compressor has gradually received attention. This paper will deeply discuss the principle, application, advantages and future development trend of waste heat recovery technology of air compressor.

First, the necessity of air compressor waste heat recovery

1. Current situation of energy waste

During the operation of the air compressor, the motor converts electrical energy into mechanical energy, and a lot of heat is generated during the process of compressed air. This heat is usually discharged into the environment through the cooling system, resulting in a great waste of energy. According to statistics, during the operation of the air compressor, about 70%-90% of the electric energy is converted into heat energy, and only a small part of this heat energy is effectively used, and most of it is wasted.

2. Demand for energy conservation and environmental protection

Air compressor waste heat recovery technology as an effective means of energy saving, not only can reduce the energy consumption of enterprises, but also reduce greenhouse gas emissions, in line with the requirements of sustainable development.

Second, the principle of waste heat recovery of air compressor

1. Source of heat energy

In the process of compressed air, the air in the motor and the compression chamber will generate a lot of heat. This heat is mainly emitted in the following ways:

Lubricating oil cooling: Lubricating oil absorbs a lot of heat during the lubrication and cooling process.

Compressed air cooling: The compressed hot air needs to be cooled to the right temperature.

Motor cooling: Some air compressors use oil-cooled motors, whose heat is easy to collect, and generally share a set of oil circuit system with the air compressor.

2. Waste heat recovery method

Air compressor waste heat recovery mainly has the following ways:

Air-water heat exchange: The heat exchanger is used to transfer the heat generated by the air compressor to the water supply to form hot water or steam. This method is suitable for occasions where hot water is needed, such as heating, bathing, cleaning, etc.

Air-air heat transfer: The heat generated by the air compressor is transferred to the air through the heat exchanger for workshop heating or preheating air intake.

Heat pump technology: The use of heat pump to promote low-grade heat energy to high-grade heat energy, improve the utilization efficiency of heat energy.

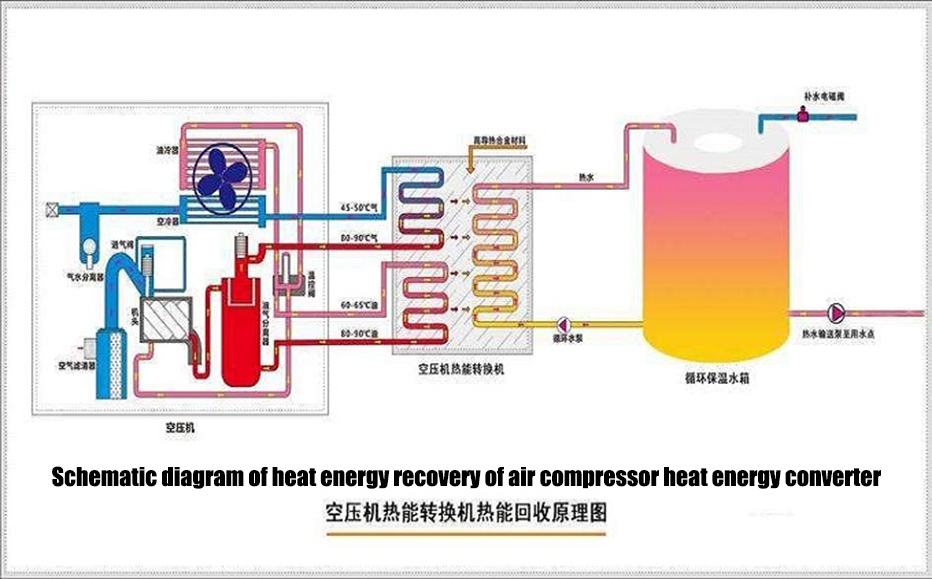

3. System composition

A complete air compressor waste heat recovery system usually includes the following parts:

Heat exchanger: used to transfer the heat generated by the air compressor to the water or air.

Circulation pump: used to transport hot media (such as water).

Control system: used to monitor and regulate the operating state of the system to ensure safety and efficiency.

Heat storage device (optional) : Used to store excess heat for emergency use.

Third, the application of air compressor waste heat recovery

1. Industrial applications

Heating: The recovered heat energy is used for heating workshops and office buildings, replacing the traditional boiler heating method.

Hot water supply: to provide domestic hot water for employees, or for cleaning, disinfection and other links in the production process.

Preheating inlet air: The recovered heat energy is used to preheat the inlet air to improve combustion efficiency and reduce fuel consumption.

2. Commercial applications

Hotels, hospitals: Provide hot water for rooms, wards, or for laundry, disinfection and other links.

Natatorium, gym: Hot water for swimming pool, shower room.

3. Agricultural applications

Greenhouse heating: The use of recycled heat energy to provide heat for the greenhouse and promote plant growth.

Aquaculture: to provide a constant temperature environment for aquaculture, improve the efficiency of aquaculture.

Fourth, the advantages of air compressor waste heat recovery

1. Energy saving and consumption reduction

Through waste heat recovery, the energy consumption of air compressors can be greatly reduced and a lot of energy costs can be saved. According to the actual application cases, the waste heat recovery system can recover 50%-70% of the total energy consumption of the air compressor, significantly improving energy utilization efficiency.

2. Reduce operating costs

The waste heat recovery system can not only save energy costs, but also reduce the load of the cooling system, extend the service life of the equipment, and reduce maintenance costs.

3. Environmental protection and emission reduction

Waste heat recovery technology can effectively reduce greenhouse gas emissions and reduce the carbon footprint of enterprises, which is in line with the national policy orientation of energy conservation and emission reduction.

4. Improve production efficiency

By recovering waste heat, a stable heat supply can be provided, improving the stability and efficiency of the production process. For example, in the application of preheating air intake, combustion efficiency can be improved and fuel consumption can be reduced.

As an effective means of energy saving, the waste heat recovery technology of air compressor has a broad application prospect. Through reasonable design and scientific application, enterprises can significantly reduce energy consumption, reduce operating costs, improve production efficiency, and at the same time contribute to environmental protection. In the future, with the continuous progress of technology and policy support, air compressor waste heat recovery technology will usher in a broader space for development.

It is hoped that this paper can provide valuable reference for readers and promote the popularization and application of air compressor waste heat recovery technology. Let us work together to contribute to the building of a resource-saving and environmentally friendly society.