Products

Two Stage Oil Injection Screw Aircompressor(Fixed Speed and VSD)

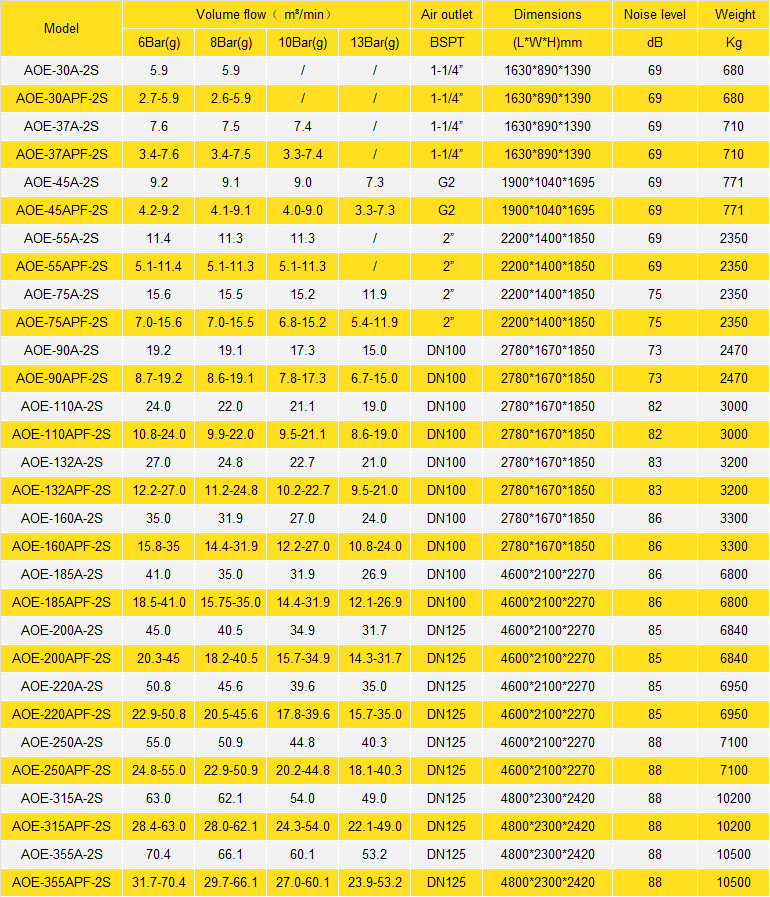

Model AOE Series

Working Power 30-355【KW】

Free Air delivery 2.7-53.20【m3/min】

Working pressure 6.0-13.0 【bar】

https://www.youtube.com/shorts/ii-tE2GhKCM

• Designed for market demand and operating conditions, the main components of the compressor system are imported from Europe, using European standard assembly line production.

• Low energy consumption. Energy efficiencylevel reaches first-class energy efficiency. Two-stage screw air compressors can save energy by 5-8% compared with single-stage compression. Reduce internal leakage, improve volumetric efficiency; reduce bearing load, increase bearing life, and extend the life of the main engine.

• Durable and stable air end: two-stage integrated air end, third-generation asymmetric rotor technology; suitable for medium-pressure compression ratio matching, high volumetric efficiency; adopt heavy-duty bearings, and the rotor is well stressed; two-stage rotors are respectively passed gear drive, so that each stage of the rotor has the best linear speed; using a large rotor, low speed design, low noise and low vibration.

• Low energy consumption. Energy efficiencylevel reaches first-class energy efficiency. Two-stage screw air compressors can save energy by 5-8% compared with single-stage compression. Reduce internal leakage, improve volumetric efficiency; reduce bearing load, increase bearing life, and extend the life of the main engine.

• Durable and stable air end: two-stage integrated air end, third-generation asymmetric rotor technology; suitable for medium-pressure compression ratio matching, high volumetric efficiency; adopt heavy-duty bearings, and the rotor is well stressed; two-stage rotors are respectively passed gear drive, so that each stage of the rotor has the best linear speed; using a large rotor, low speed design, low noise and low vibration.